No body does an indution kit for a 1.6fsi, probably because the standard air filter is housed in the engine cover so it a bit hard to do one. I contacted a few companies about making one but as soon as they learnt the details they stopped talking... Time to make my own then! I had one aim in mind, do it with the stock mounting that goes over the throttle body and to not have to move the maf.

What you need.

Engine cover

Air filter/pod filter

Aluminium pipe (2.5" is the biggest that will fit)

Silicone bends 90 x 3

Clamps

flexible silicone adhesive

Basic tools, a dremel and angle grinder can help.

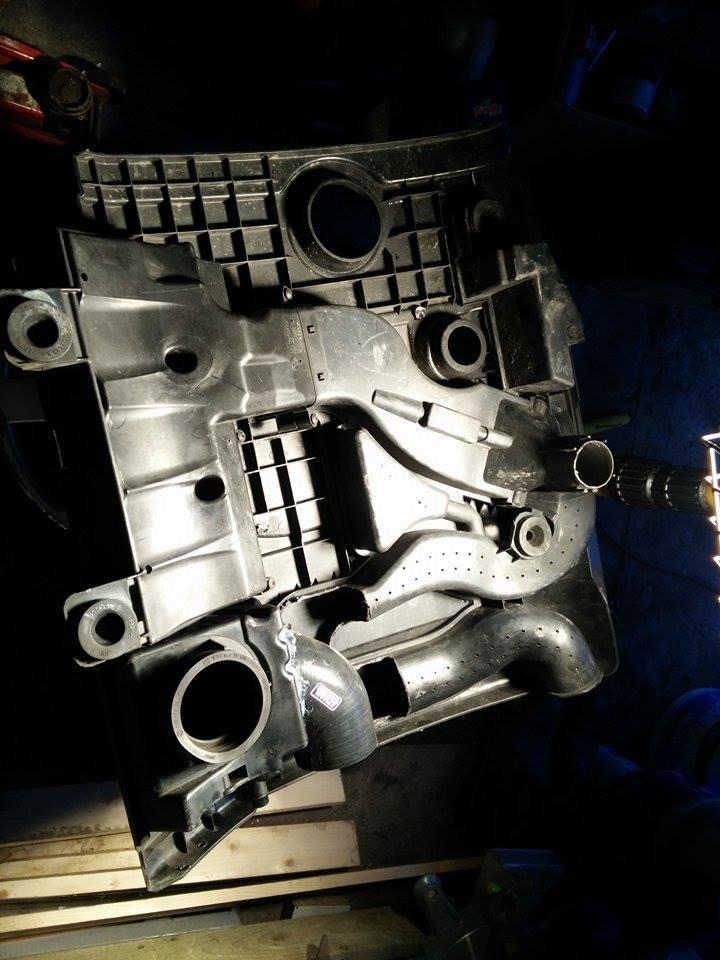

This is what it looked like to begin with , the pod filter attached to the cover, kind of pointless as it has a million miles of pipe work before it reaches the engine, and I see a nice gap between the engine and battery box

First of all you need the cover off, I wont cover this as there are many videos etc how to do it, and if youre attempting this im going to asume you can manage a few basic things

Now once you have that, you can remove the stock filter box or leave it on, I was fitting a new bit as the mounts were broken so mine came off, but i did find it helped later having the space.

Once you can done that, time to start cutting, I cut a section out using a hack saw and a dremel. Then used the dremel to cut the final bit on and snap it off as I struggled to get it all the way in.

Time to smooth off those edges, the dremel and sanding attachment comes in handy here.

Next up is cutting a hole, a hole saw would help massively here but I couldn't find mine so had to use the dremel (It was cleaned up after)

I missed a picture but you need to cut one of the hoses at an angle to help it sit flush with the box, you will see what I mean if you do this yourself. After that you need to start sticking it on, get the silicone adhesive out and start putting it on, a g clamp would help but again mine had gone walkies so I held it for 5 mins then propped it up with random stuff.

It was taking too long to set, bring out the heat!

Once its set reasonably hard, place it back over the engine (dont need to clip it on) and start measuring up what lengh straight bits you need, then get cutting, I used a 7cm and a 20cm.

Not nessory but I created a little support bracket out of a bit of scrap metal and an old bike QR and attached it to one of the spare holes that are used to hold an air box on.

Cover back on, I left the standard paper filter in there for now as I was short on time but plan to plasti weld the gap up so there would be no need for it.

While it was drying, I used some of the cut off hose to help support it by wedging it between it and the cover and siliconing it down

It was dark and cold by the time I was happy the silicone had set so didnt get many pictures, but basiially you attach it back to your car the way you normally would, then gently start pushing the bits together, you can put a few bits together first like the filter and the bend to make it quicker and easier. Once youre done it should look something like this

The edges are a bit rough but for a first attempt I am pretty happy, if I had longer I would have taken my time more and got it spot on