Well, not today. But recently.

Burnt out my clutch.

I wasn't really surprised as my car is over 100,000 miles and has been running stage 2+ for about the past 2 years.

Reversing up a steep driveway with a trailer finally killed it.

I was having to ride the clutch quite a bit as I couldn't see clearly where I was going. The next thing I knew the clutch was fully released and I wasn't moving or stalled. A big cloud of smoke came from under the hood and I decided that where I was would be good enough for loading up the trailer. (And to let the clutch cool down so I could still drive home).

So I bought a new Luk clutch kit and Dual Mass Flywheel. As if that didn't set me back enough, I decided it was the perfect time to install a limited slip differential too.

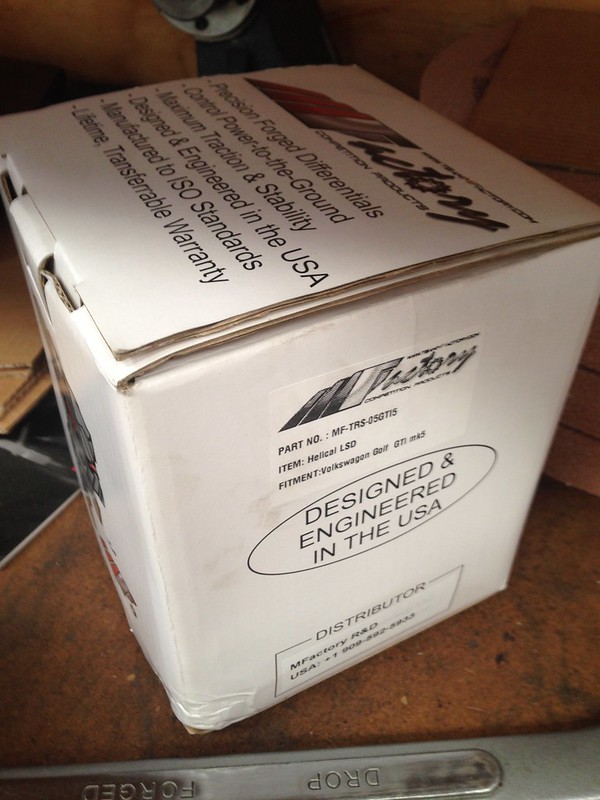

So I ordered in one from MFactory. After researching all the different brands a year ago I knew this was the one I wanted.

So on to the photos of the install.............

Here's the LSD. Trust me, it's in there. Never actually took a photo of it.

I didn't have an engine support so had to make my own. Here it is in use.

This support was very useful also for installing the gearbox back into the car as it is bloody heavy. I was able to use a rachet tie down to lift it up as there was no way I was going to be able to lift it up by hand like the guy in the youtube video that I used as my guide. It was difficult enough lowering it out of the car with my trolley jack.

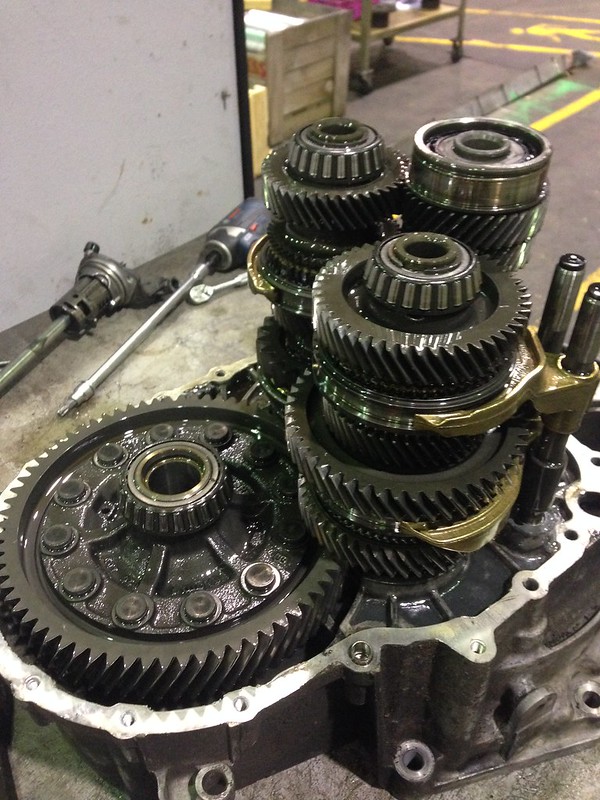

Got the sucker out ready for the LSD.

Opened up the gearbox and took a whole bunch of photos so that I'd be able to work out how it all went back together.

After removing the bearings from the original diff I inspected them for wear. Fortunately they were both good as I needed to reuse them and there were none available in New Zealand on the shelf and I hadn't ordered any from overseas.

Next step was removing the ring gear from the original diff to swap it onto the new LSD. On my youtube guide video they attack the rivets with a drill, cold chisel, air powered chisel and it still takes them 3 hours! I stuck mine it the lathe and machined off the heads, then set it on the bench sitting the ring gear on an old bearing shell and punched the rivets out. Took 20 minutes total!

From here I didn't follow the video. They say to remove all the shims from behind the outer bearing shell, then re-install the bearing shell along with the LSD with the bearings on it into the gearbox housing and do up some bolts. Then you are supposed to push the LSD all the way up and down to measure the end float in order to determine what thickness shims to use to achieve the desired amount of preload.

I just measured the diference in heights between my original diff and the LSD.

My LSD was 0.06mm shorter so I added a 3 thou shim (0.0762mm) that I cut out of some shim material that I had.

From there it was as they, installation is the reverse of removal. Putting in the new clutch and DMF was fairly straight forward. I should have taken a few more photos of where the different bolts go that mount the gearbox to the engine as I was scratching my head for a while there.

I put in new gearbox oil after everything was in place and took it for a test drive. All good, sweet.

I need to replace my gearbox oil again soon (probably this weekend). And another wheel alignment probably wouldn't go amiss after dropping the front wishbones, although it all feels fine so far.

Haven't had a decent opportunity to try out the LSD as such yet but hoping it will all be worth it.